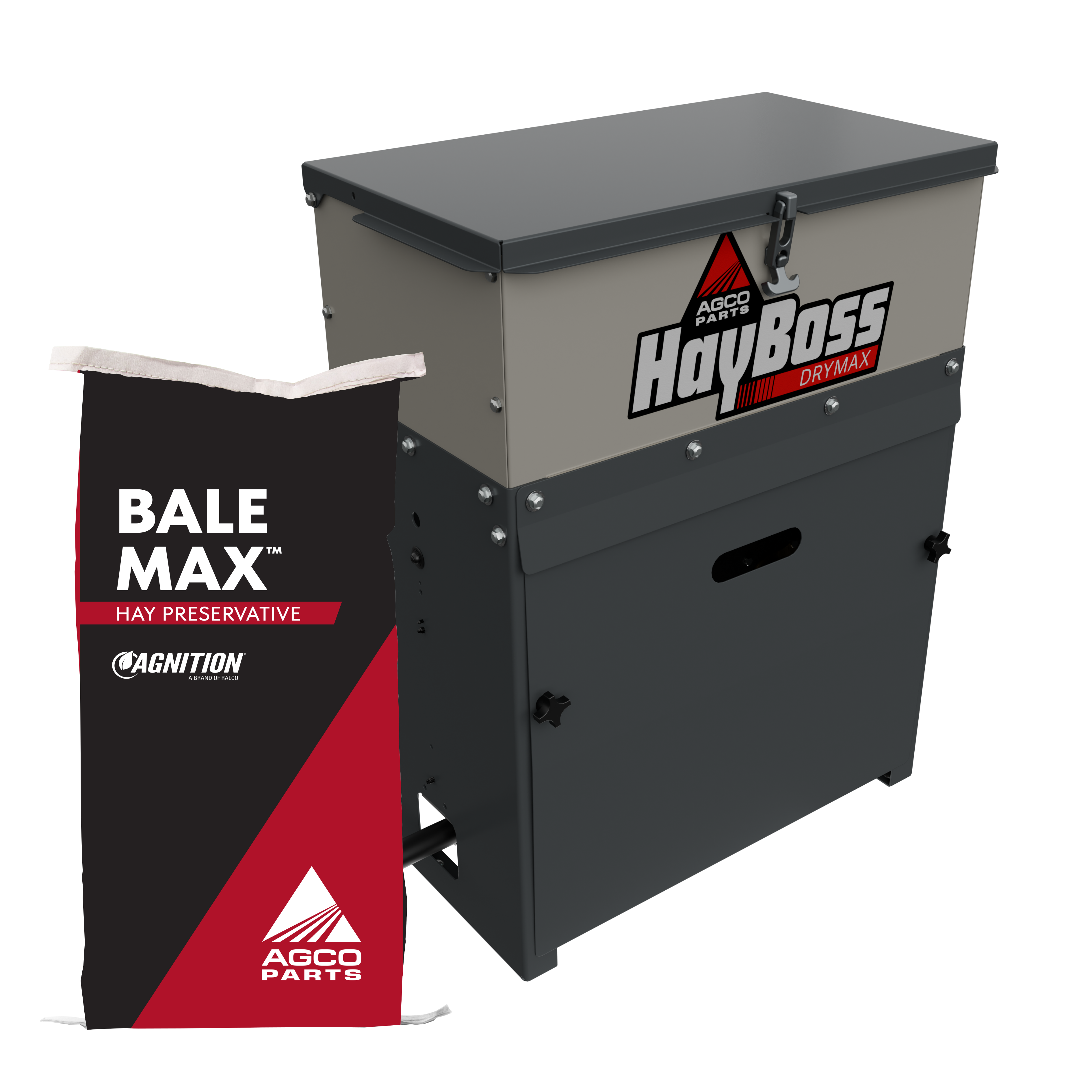

HayBoss® DryMax™ & BaleMax™

HayBoss® DryMax™ & BaleMax™

Unlock more time to bale premium hay with HayBoss® DryMax™ & BaleMax™.

Available for Hesston by Massey Ferguson large square balers HayBoss® DryMax™ gives growers an advanced, automated dry granular preservative applicator solution to accurately apply preservative.

Looking for a preservative that can be applied with confidence, look no further than BaleMax™ featuring Microbial Catalyst® technology, it preserves higher moisture hay and maintains hay quality over time while reducing the risk of heating and spoilage.

Available in North America

DRYMAX™ OVERVIEW

LARGE SQUARE BALER KITS

| KIT | AGCO BALER MODEL | PART NUMBER |

| Large Square Baler* | 2233, 2234, 2234XD, 2244, 2250, 2270, 2270XD, 2290, 2140, 2150, 2160, 2170, 2170XD, LB33B, LB34B, LB44B and equivalent models | ACX5534170 |

*Baler serial number must end in Cxxxxx or newer (model year 2013 or newer)

ELECTRICAL ACCESSORY KITS

| KIT | DESCRIPTION | PART NUMBER |

| Universal ISO Standalone Kit - Battery** | Kit includes standalone ISO harness, Datatronic 5 terminal, and mounting hardware. Use when not connected to electronics of baler or connected to ISO of tractor. | 700964684 |

| Non-ISO Battery Harness** | Kit Includes battery harness for power only. Use when connected to the electronics of baler. | ACX5027560 |

*Use of electrical accessory kits depend on how the customer has the ISO terminal(s), or lack-ther-of, set up in the cab. Kits are universal in nature since ISOBUS can be configured in a variety of ways on a particular baler and tractor.

BALEMAX™ OVERVIEW

BaleMax™ is a dry granular product that preserves higher moisture hay and maintains hay quality over time while reducing the risk of heating and spoilage.

BaleMax™ preserves higher moisture hay for:

- Increased Baling Flexibility

- Reduce Heating

- Preserve Nutrients

- Less Spoilage

BaleMax™ is comprised of:

- Organic Acid

- Proprietary Inoculant Blend

- Microbial Catalyst® Technology

Benefits of BaleMax™:

- Start earlier in the day

- Bale longer at night

- Keep baling in humid conditions

- Save more leaves

- Reduce heating

- Lock-in nutrients

- Reduce field curing time

- Will not rust equipment

BALEMAX™ STUDIES

BALEMAX™ HAY PRESERVATIVE

| CONTAINER | DESCRIPTION | PART NUMBER |

| Half-Pallet | US Only - (20) 50lb plastic lined paper bags (covers 500 tons of hay treated) | ACX5553410 |

| Half-Pallet | CANADA Only - (20) 50lb plastic lined paper bags (covers 500 tons of hay treated) | ACX5679210 |

| Pallet | US Only - (40) 50lb plastic lined paper bags (covers 1000 tons of hay treated) | ACX5551520 |

| Pallet | CANADA Only - (40) 50lb plastic lined paper bags (covers 1000 tons of hay treated) | ACX5679200 |

SOFTWARE UPDATES

Coming soon

SOFTWARE CHANGE NOTES:

Coming soon

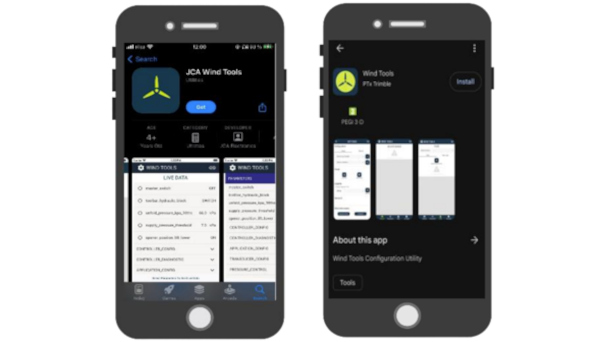

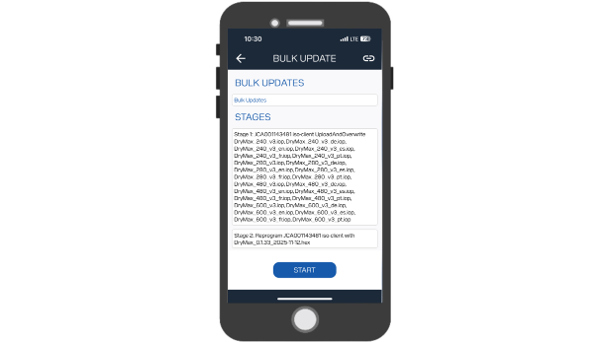

Software Installation Instructions

1) Download and install "JCA Wind Tools" from your mobile device application store. You may also find it as "Wind Tools" by PTx Trimble.

2) Download the latest software from the HayBoss® DryMax™ & BaleMax™ AGCOACCESS page.

Coming soon

3) Go to your device's Wifi settings and connect to "DryMaxJCAxxx.." With the default password "12345678".

4) Return to the Wind Tools app. You should now see the connected icon in the top right.

5) Select "Local".

6) Select the correct .zip file from your device's memory.

7) Select "Start".

8) The application then executes the required stages and then restarts the system. Software update is now complete.

FAQ

- What model of balers is the HayBoss® DryMax™ applicator compatible with?

- DryMax™ is compatible with 2100 Series** and newer Hesston by Massey Ferguson Large Square Balers.

**Depending on baler model year.

- What is the recommended application rate for the BaleMax™ granular preservative?

- Apply to cured hay crop at a rate of 2 lb./ton at the recommended moisture levels.

- How much does the hopper hold?

- 4.0 cu ft, or about (4) 50lb bags of BaleMax product.

- Is there a bin level sensor on the system?

- No, but the blockage dectection system will alert the operator when the bin is empty or not distributing product. The bin level indication on the user interface is a "gas gauge" type display based on the operator adding the amount of product they physically added to the hopper.

- When will DryMax systems be available for other balers?

- AGCO is currently still testing and developing systems for the round baler and small square baler markets. More information will be available on these new products in 2026!

- Where are the DryMax and BaleMax products manufactured?

- The DryMax applicator is manufactured in Kansas and BaleMax is manufactured in Minnesota - both in the USA.

- When should I choose a granular or liquid preservative product to apply on my hay?

- Choose based on equipment, handling preference, feeding/marketing goals, and cost! Both options maintain hay quality - granular offers added palatability and simplicity, while liquid provides flexibility for established systems and higher application ranges.

- Can BaleMax be used in any granular preservative applicator?

- Yes! Some other granular preservative products can work in the DryMax applicator too.

- Is the BaleMax product safe from humidity while in storage?

- Yes! BaleMax is packaged in a sealed, plastic and paper bag. The plastic liner protects the product from moisture and humidity, but it is always recommended to store unused product in a dry, covered location out of the sun for the best results.

- Is the DryMax universal?

- The DryMax operates on the standardized ISOBUS communication protocol. This means it can be operated via any ISO terminal on the market. For the optimal results and use of the Baling Rate Management feature, it must be configured on approved AGCO baling equipment. The DryMax can also be configured to run in a fully universal mode that does not rely on any baler information so the operator can adjust rates manually as they see fit. The universal mode still has some of the automatic functions available for use like the crop eyes and blockage detection.

- What is the Baling Rate Management feature?

- It is no surprise that not all windrows are consistent or equal. The need for changing the baling rate while applying applicants can greatly affect a producer’s bottom line. If you are putting a “blanket rate” of preservative down, you could be under or over-applying. The baling rate management feature of the DryMax enables the applicator to more accurately apply product with the help of reading live baler data like bale length, flake formation, bale weight and baling rate. Only compatible with AGCO baling equipment, live data from the baler can automatically control the application rate so the operator doesn't have to!

- Can the DryMax applicator be used in conjunction with an inline steamer?

- Yes, there is a bracket that comes with every applicator to mount the deflector around the steam manifolds in the feeding area.

- Do I need a scale to calibrate the system?

- Yes, you do need a small platform or hanging scale (minimum 1/10th lb accuracy) to weigh the filled calibration bag once complete with the automated calibration cycle. This is critical to ensure the system is maintained and adjusted for precise application. A typical calibration cycle will transfer about 3-6 lbs (varies based on product used) per cycle into the bag, so a high-capacity scale is not preferred or required.

- Can I install this system on a different make/model of baler?

- While the system was specifically designed and validated for specific AGCO models of equipment, it may be possible to install it on other makes/models. However, please note that installations on non-AGCO supported equipment will not be officially supported by AGCO. This means we cannot guarantee performance, compatibility, or provide technical support for such configurations, and AGCO assumes no liability for issues that may arise from non-standard installations.

- How long does it take to install on a large square baler?

-It should take no more than 12 hours to install on a large square baler.

Last update 25.11.2025